BRIDGING THE GAPS

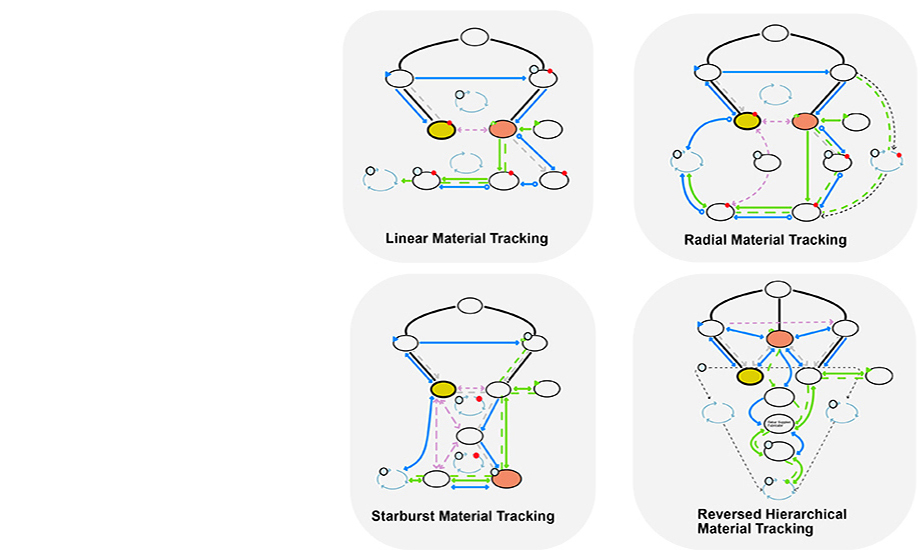

Rebar Tracking and Designing Out the Waste. MBJ collaborated with Mortenson to study waste flow of rebar within the design and construction supply chain. The research tracked the various stages of rebar life cycle, from material creation to design to construction and post-construction recycling. Process models were developed to capture current state of practice with the aim to identify waste points that inform ideal state of practice. The four project progressive system structures included linear material tracking, radial material tracking, starburst material tracking, and reversed hierarchical material tracking.

Throughout the investigation process, we found disconnection between rebar supply chain team members and their perspective instruments or services. There was lack of clarity on specific member activities and responsibilities outside of their own. There was also lack of time and capital as well as coordination in tools and instruments. We observed rebar tracking to involve piece-mailing disjointed portions of the material’s story and no established best practices to the rebar supply chain process.

While the structural engineer is at the head of the rebar supply chain system, a collective effort and responsibility of all parties seems appropriate in mitigating its current fragmentation; as all parties are collectively working under the project’s schedule and budget.