AN EMBODIED CARBON COMPARISON

Embodied Carbon Study of ICF vs Traditional Wood Framing. MBJ was the structural engineer for a multi-family residential stick-on-podium development focused on environmental stewardship and healthy living. To achieve that mission, the building is pursuing Living Building Challenge Petal Certification. This emphasis on sustainability balances a focus on operational carbon and embodied carbon of the full project.

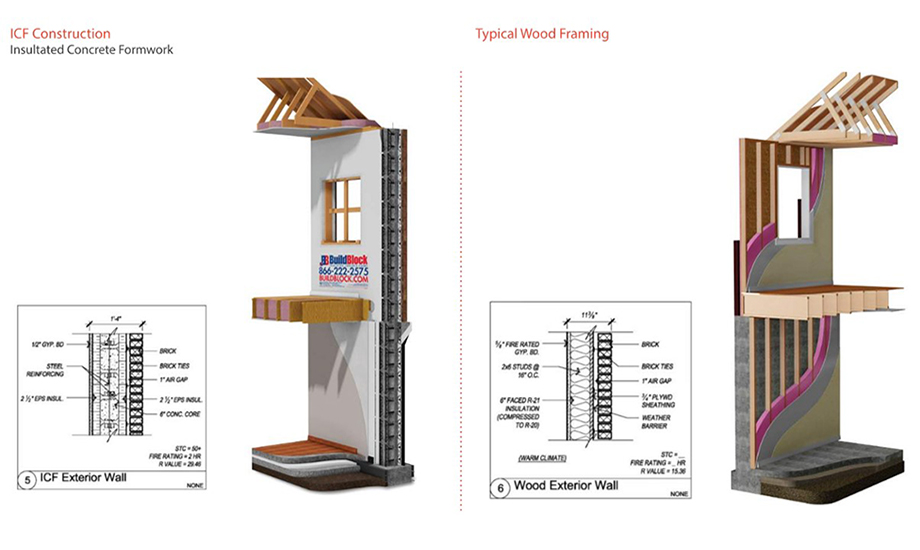

In order to inform the team’s decision on building system selection, MBJ performed Life Cycle Analysis (LCA) to compare the embodied carbon of Insulating Concrete Form (ICF) exterior walls versus traditional wood wall framing. Simultaneously our design team partners at Emanuelson-Podas studied the impact of each wall type on R-Value and air leakage. MBJ used Tally to complete the LCA of each wall type considered. For the ICF walls and basement walls, MBJ worked with a local cement supplier to procure a low carbon mix design. Several wall cases were studied using a standard concrete mix or the low carbon mix, using 6” ICF, 4” ICF, and traditional wood walls for the above grade walls and using cast-in-place concrete, ICF, and CMU walls for the below grade walls. Where ICF walls were used below grade, an additional interior finish of gyp and wall panel was required. This was not needed at concrete or masonry below grade walls.

Excluding biogenic carbon. the LCA results indicated that the use of traditional 2×8 wall framing over a 16” masonry wall had almost 40% less embodied carbon than the lowest carbon wall assembly that included ICF panels (4” ICF wall panels over 14 ½” cast-in-place basement walls using the low carbon concrete mix). Based on the significantly lower carbon and favorable results from the mechanical study of R-Value and air leakage, the project moved forward with the use of traditional wood wall framing.