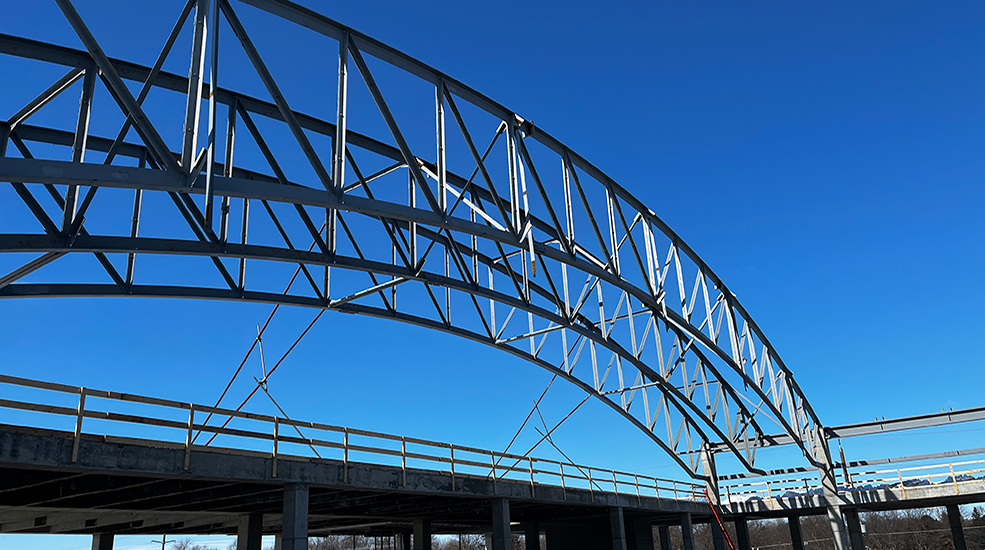

To expedite the construction process and eliminate the lengthy lead time typically associated with a structural steel frame, the more conventional choice for an arena, we opted for cast-in-place, reinforced concrete for the primary structure. For the concourse and low roof, a wide-module 21” deep system with 24” x 24” concrete columns was selected. Additionally, we incorporated two strategically positioned, highly efficient 8” concrete shear walls, a rarity in arena construction, offering exceptional resistance to lateral loads. Raker beams, serving dual purpose of resisting lateral loads plus code required program loads, were manufactured with precast concrete instead of steel. The primary high roof was engineered with 12’ deep structural steel trusses at 10’-8” OC, spanning 153’ and supporting 3”-20 gauge acoustic roof deck. The trusses are a “barrel vault” shape with top chord radius of 198’-0”. The entire structure, including the ice sheet, is supported by driven steel pipe piles.

MBJ’s foundation design accelerated both the design and construction phases while delivering substantial value and critical performance criteria. Following a thorough examination of multiple piling options, rather than opting for the initially recommended proprietary soil correction procedure, we recommended that a qualified subcontractor be retained and who installed approximately 575 x 45′ long steel pipe piles. This foundation system was installed in less than 30 days following mobilization and without any change orders for unforeseen conditions. Leveraging MBJ’s cast-in-place concrete solution enabled the contractor to begin work on the main building frame much earlier than would have been feasible with structural steel. The pile supported structural slab-on-grade provided for the particularly small settlement performance required by the specialty consultants to maintain ice integrity. Cold-formed steel exterior walls strategically implemented at multiple locations also provided cost savings over CMU.