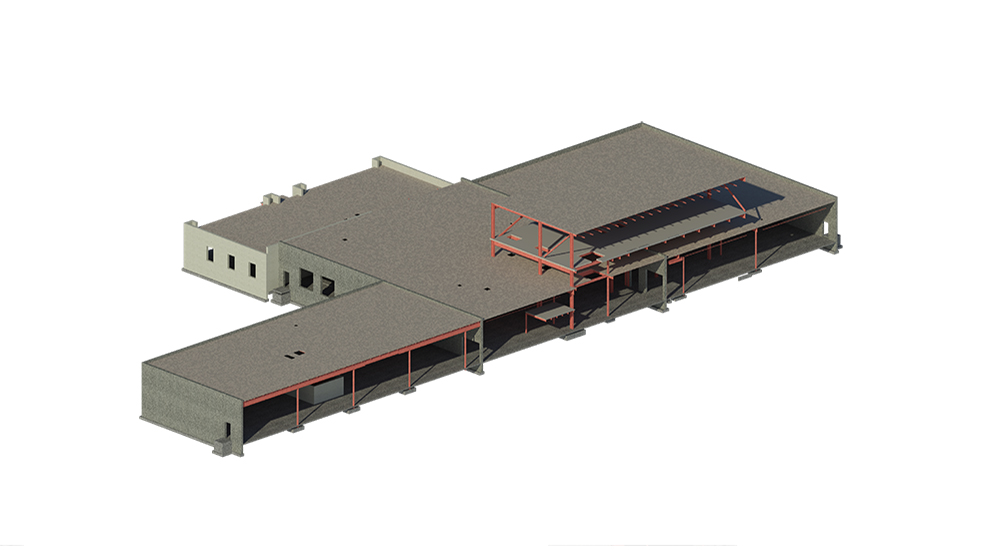

In order to address the increased demands on the building infrastructure, MBJ provided structural engineering for a new rooftop penthouse to house necessary mechanical and electrical equipment. The penthouse is a fully enclosed steel structure elevated above the existing roof structure to avoid impacting snow drift on the roof. The penthouse is supported on independent columns and connected to the building below with a stair tower, a hoist way for materials and shafts for any mechanical piping or ductwork.

Additionally, the main building required extensive removal of primary structural elements to meet the programmatic vision of the owner. Steel columns and large portions of load bearing concrete walls were re-supported to be less obtrusive to the manufacturing layout. A cold-formed metal-framed walkable ceiling supports mechanical and electrical access and a new CMU and precast concrete hazmat room enclosure helps to facilitate the new manufacturing process demands.

While this project required major structural measures to bring the facility up to the owner’s needs, MBJ continually worked with project team members to minimize the structural impact on the building and optimize outcomes when structural measures needed to be taken. Our team worked closely with project partners to develop economical solutions which kept the project in line with the owner’s budgetary expectations.